TIGHITCO, Inc. is a trusted Part 145 FAA and EASA certificated repair station specializing in overhaul support for rotorcraft and fixed-wing aircraft components.

Reliable Part 145 FAA and EASA Certified Repair Station

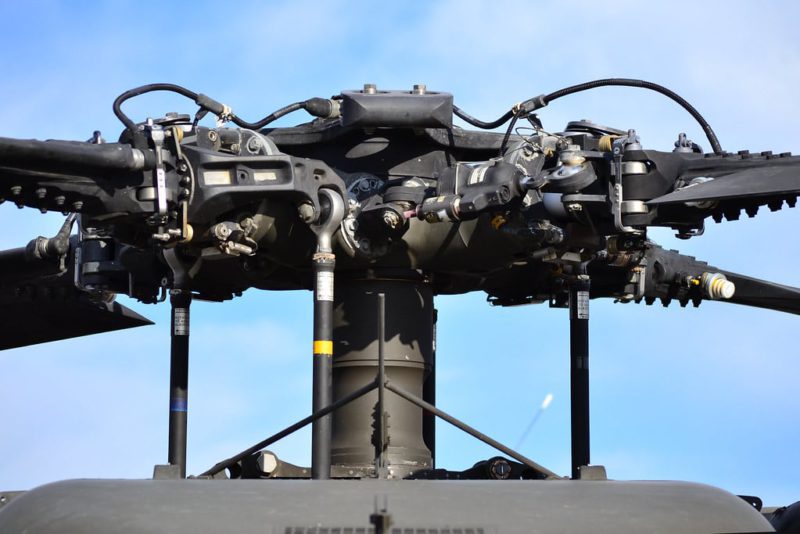

When you need quality overhaul & MRO services for rotorcraft or fixed wing aircraft components, count on TIGHITCO. We help government and OEM service centers and operators with scheduled maintenance, inspections, testing and repairs on helicopters and fixed wing aircraft. Our experienced aviation technicians provide reliable overhaul support services to get your aircraft back in the air as quickly as possible.

- Excellent ResponsivenessTIGHITCO's team is excellent on responsiveness and working with their customers to ensure open items are resolved and parts are delivered. The program, sales, engineering, quality, and operations teams are always willing to work with us and ensure parts delivered in a timely manner.

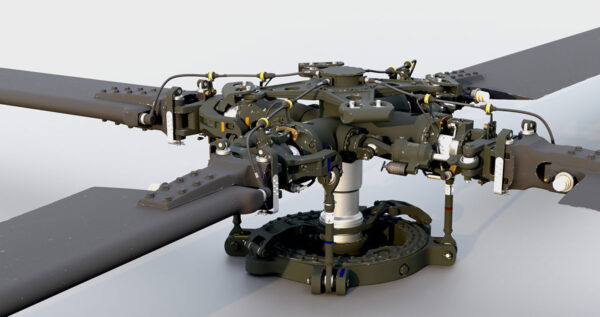

Overhaul and Repair of Fixed Wing & Rotorcraft

Components

Maintenance and Repair Services

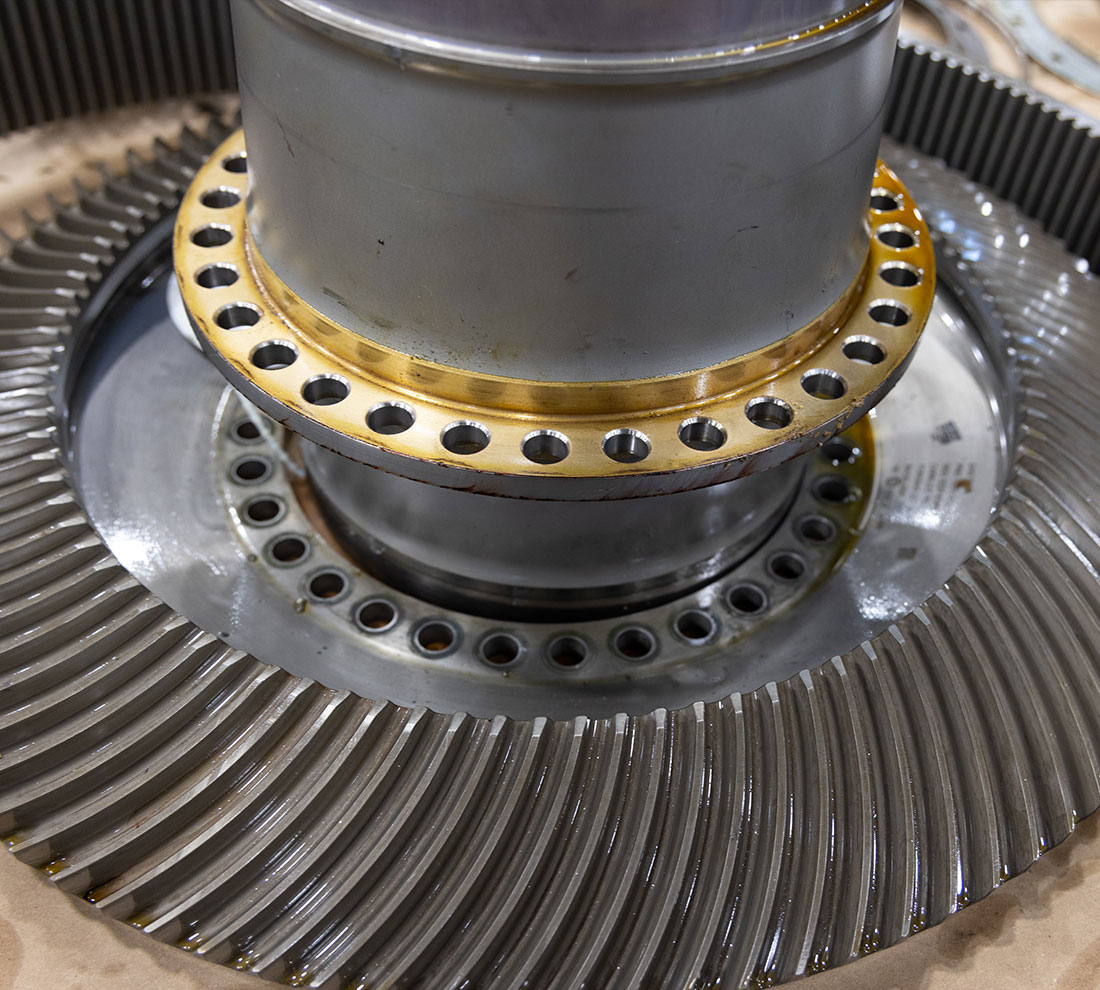

Overhaul Capabilities

Non-Destructive Testing & Inspection Capabilities

Quality Helicopter Rotor Blade Repairs

Cracks:

- Metal blades: Skin cracks can be stopped with early detection and patching.

- Fiberglass blades: Cracks may not need repair unless exceeding manufacturer limits.

- Nitrogen-filled blades: Leaks are detected early through built-in indicators or halogen detectors.

Corrosion:

Prevented through primer, paint, and maintenance. Treatable to prolong blade life, or we can recommend replacement if necessary.

Balance problems:

Vibrations can indicate water intrusion or shifting components. Loose ribs and water are common causes, which we can fix to restore a smooth flight.

Painting issues:

Improper painting can cause balance issues and affect blade function. We can remove excess paint and repaint for improved performance.

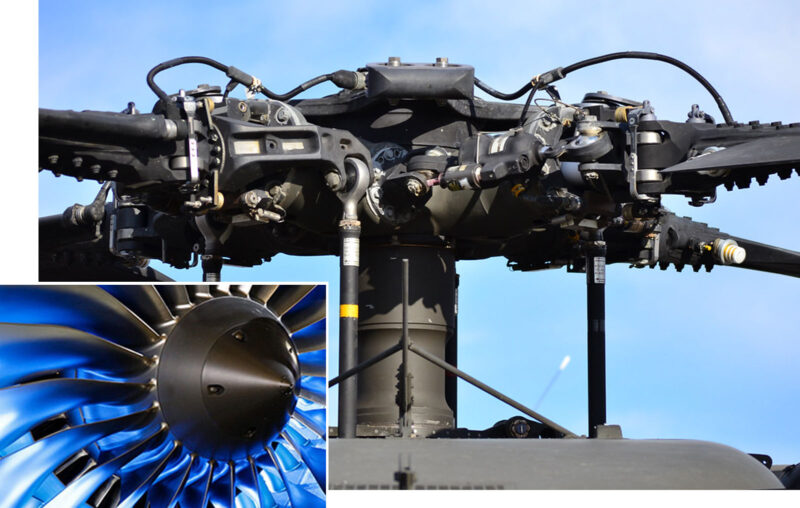

Rotor Repair Process

1. Disassembly, Cleaning, and Inspection:

Blades are removed and thoroughly examined. Inspection methods include:

- Visual inspection with a magnifying glass

- Acoustic impact test (coin tap test)

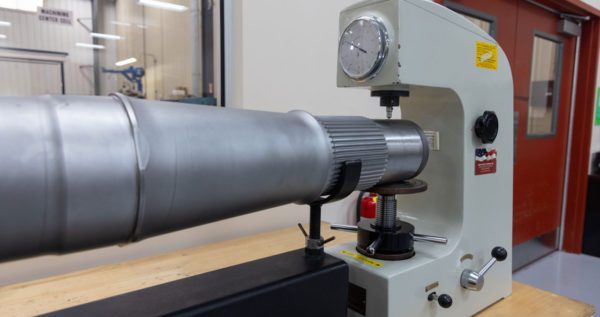

- Hardness tests

- Moisture tests

- Ultrasonics

- X-rays

- Thermography

2. Overhaul & Repair:

- We address the specific problems identified during inspection, following manufacturer guidelines.

- Repairs are made to restore blade safety and functionality.

3. Final Assembly and Test:

Repaired blades are reassembled and rigorously tested to ensure they meet safety and performance standards. You receive your blades back, ready for safe and smooth flight.