TIGHITCO, Inc. is your trusted partner for complete metallic, soft goods and molded insulation product manufacturing for industrial and aerospace applications.

High-Quality, Custom Insulation Solutions

If you’re looking for a long-term partner who can deliver high-quality, custom insulation solutions for your industry, count on TIGHITCO. We specialize in encapsulated metal, metal foil, soft goods and sewn insulation design and fabrication for aerospace, industrial, energy and industrial applications. With our extensive library of materials, we can find a thermal solution for even the most challenging environments. We take a cross-functional approach to design, optimizing for performance, manufacturability and quality.

- Excellent ResponsivenessTIGHITCO's team is excellent on responsiveness and working with their customers to ensure open items are resolved and parts are delivered. The program, sales, engineering, quality, and operations teams are always willing to work with us and ensure parts delivered in a timely manner.

Industries We Serve

Top Industrial & AerospaceInsulation Products

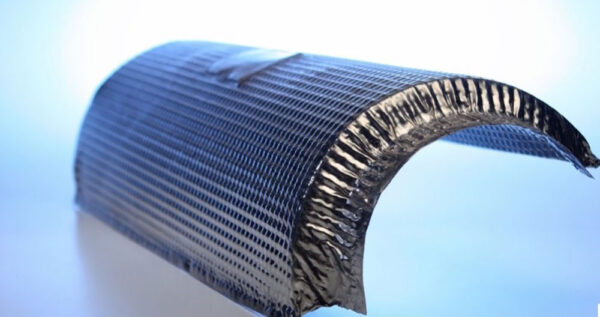

Metal Foil Insulation Blankets

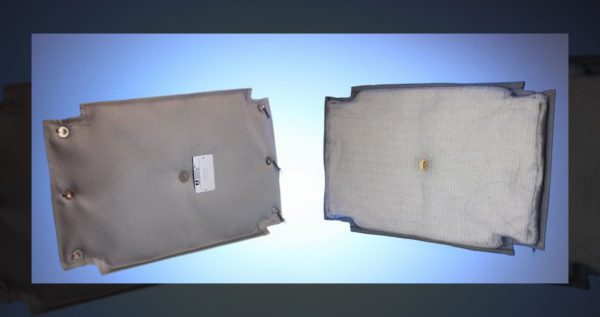

Sewn Insulation Blankets

Molded Insulation Blankets

Insulation Design & ManufacturingCapabilities

Insulation Design & Manufacturing Capabilities

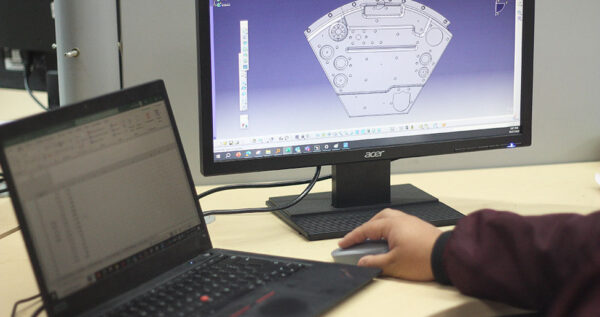

Design & Engineering Capabilities

Non-Destructive Testing & Inspection Capabilities

Your Trusted Source for Insulation Products Manufacturing

TIGHITCO is an experienced, responsive supplier for insulation product design and manufacturing. We partner with OEMS and service providers around the world to deliver turnkey solutions, conceptual designs, thermal analysis, source-controlled engineering, build-to-print programs and more.

With more than 30 years of experience in design and development and a lean manufacturing approach, we’re constantly evolving to provide better, more cost-effective insulation solutions for our customers. We’ll be here to support you long after the sale with a warranty and responsive service. And with five locations in the U.S. and Mexico, we offer the flexibility to deliver cost-effective production without sacrificing quality.

Quality Control

- Part/component qualification testing

- Vibration testing

- Thermal conductivity testing

- Humidity testing

- Environmental durability testing

- Tensile testing

- Peel tests

- Ultrasonic inspections

Equipment

- Metal trimmers and texturizers

- 70-ton press

- Beetle, seam, and spot welders

- Lectra cutting machines

- Curing ovens

- Vacuum equipment

- Certified molds

- Flatbed, free arm, edge binding, and CNC sewing machines

- CNC 3-axis routers

- 36″ diameter, 4000 PSI fluid cell hydroforming press

- Press brakes

- Heat treatment & artificial aging furnaces

- Aluminum processes equipment

- Thermal analysis & design using CFDesign™ software.